What We Know

The use of hospital Emergency Departments (ED) in the U.S. has been rapidly rising, the result of patients pushing them into service for every immediate medical need. The Institute of Medicine at the National Academies says, “EDs today provide much of the medical care for patients without medical insurance. Insured patients increasingly turn to the ED during times when their physician is unavailable, such as evenings and weekends, and they are often sent to the ED for tests and procedures that their physician can’t easily perform in the office. In some rural communities, the hospital ED may be the main source of healthcare for a large percentage of residents.” *1

In a 2006 report, the institute said there were “113.9 million ED visits in 2003, up from 90.3 million a decade earlier. At the same time, the number of facilities available to deal with these visits has been declining. Between 1993 and 2003, the total number of hospitals in the United States decreased by 703, the number of hospital beds dropped by 198,000, and the number of EDs fell by 425.” *2

First-hand knowledge of the problem can be seen at Washington Hospital Center (WHC) in Washington, D.C., the largest trauma center in the nation’s capital. In the fall of 2006, WHC leaders reported that it was seeing 75,000 patients annually in a facility designed in 1988 for 37,000 annual visits.

Beyond the press of day-to-day patients, emergency departments are pushed beyond their limits in catastrophic events. A recent survey conducted for the U.S. Congress reported that on March 25, 2008, at 4:30 p.m., “The Level I trauma centers surveyed had no room in their emergency rooms to treat a sudden influx of victims. They had virtually no free intensive care unit beds within their hospital complex. And they did not have enough regular inpatient beds to handle the less severely injured victims. The shortage of capacity was particularly acute in Los Angeles and Washington, D.C.”*3

Further complicating a surge in demand is the high risk of hospital-acquired infections. These infections are estimated to occur in five percent of all acute-care hospitalizations. The Centers for Disease Control estimates that 1.7 million such infections occur annually nationwide. *4 A surge in an emergency department demand can promote the spread of infections, whether caused by a biological terrorist attack, an epidemic, or bacteria found in a hospital.

Understanding the Challenge

Located in one of the most likely cities to be hit by terrorist attacks, WHC has been leading a federal initiative to design and prepare EDs to meet the surges in demand created by natural, biological, accidental, or terrorist events. After several years of concept development, and the support of Senators Bill Frist, a physician, and Arlen Spector, a team headed by Chief of Emergency Medicine Mark Smith, M.D., launched ER One in 1999.

The initiative was framed “to design and demonstrate the concepts, features, and specifications for a new type of all-risks-ready emergency care facility, one optimized to manage the medical consequences of terrorism and emerging illness. ER One will provide emergency medical care during a crisis situation (i.e., terrorist attacks or epidemics) and will function as the hospital’s emergency department during daily operations.” *5

Smith, who has spent his career as both a teacher and practitioner of emergency medicine, joined the staff of WHC in 1995. Previously, he had been chairman of Emergency Medicine across town at George Washington University Hospital for 13 years. Smith and colleagues pursued and secured federal funding to study the best available ideas in emergency preparedness and emergency department design. To gather those ideas, a series of task forces were convened, bringing together 240 experts from organizations such as hospitals, universities, industry, the military, and international agencies.

“The ideas that people had to come up with fell into one of three dimensions: capacity, capability, and security,” Smith says. “These were ideas that people designing EDs had not given much thought to.” They studied key issues such as how to expand capacity by five times without catastrophic failure, how to deal with highly contagious patients and contamination, and how to keep the facility operating even if it suffered damage from an attack.

Among the topics addressed by the task forces were trauma, radiation, biodiagnostics, transportation, security, logistics, pediatrics, and mental health. They brought to the forefront 10 key problems with current design that affect how EDs function in a crisis:

1. Inadequate surge capacity (not scalable)

2. Catastrophic degradation under stress

3. Unsafe re-circulated air

4. Unsafe surface contamination

5. Inadequate arrival/departure capacity

6. Poor control of entry points

7. Poor data availability

8. Poor external and internal communications

9. High dependency on external utilities

10. Inadequate decontamination capability

The expert task forces were charged with providing evidence for both problems and proposed solutions. Breaking out of the typical local orientation of the healthcare industry, they looked beyond the medical community for solutions used in other industries. For example, airport vehicle traffic control systems were studied to understand how to deal with large volumes of arriving and departing ambulances. Financial offices were studied for systems of data visibility and communications.

Even before the start of the ER One project, Smith says that design principles were being formulated to guide the project. Smith, who started his college career in computer sciences, had previously used similar principles when he led an information systems software project for the hospital. As over 300 ideas from the ER One project were incorporated into a design study, a set of principles emerged that guided the project. (See “Design Principles for ER One”)

Problem Statement

With the design study in hand, the challenge for the ER One team was to go beyond concept to construction. Designing a responsive ED involved answering a battery of questions:

-

Could they develop materials that are less likely to be contaminated by bacteria?

-

Could they create a space that is practical for daily operations but could be expanded quickly to meet a demand surge?

-

Could they make the ED more accessible to a surge in ambulance arrivals?

-

Could hallways, waiting rooms, foyers, and even the nurses’ station be designed to convert into treatment areas if they are needed?

-

Could they move from catastrophic collapse of systems in a surge to gradual degradation as demand approaches capacity?

Solutions

WHC began answering these questions in the second phase of ER One dubbed “Bridge to ER One.” This second phase involved the use of federal funding to expand its ED. The project began in late 2004. Noted healthcare interior designer and author Barbara J. Huelat of the Alexandria, Virginia-firm Huelat Parimuchat, who served on the ER One project team, was selected to lead the design. One of the hospital’s goals with the project was to increase its treatment bays by 62 percent, expanding from 29 to 47 bays. *6

Huelat’s design approach matched the project’s evidence-based approach. Rather than making design decisions based on trends, Huelat gathered evidence from multiple sources, such as research studies and observations of the client’s operations and those of similar facilities. Huelat explains that the team was “trying to accomplish something that has never been done: Expand from an everyday inner-city ED to the potential of handling a major catastrophe. We began by looking at other industries and to science for answers.” These examinations led the team to choose materials that were uncommon in hospital design and furniture that is more commonly found in offices.

Huelat says that what the staff of an ED does is similar to that of stock traders. They require a lot of information displayed on screens, and they sit briefly at the workstation and then move on to something else. In the same way, the team examined the issues of sterile environments by looking at clean rooms in the computer industry as well as hospital operating rooms.

Designing the Bridge to ER One was a process of planning, testing, and then revising. Corian, a nonporous, solid material, was tested on walls and ceilings because the surface can be cleaned easily, but the design had to be changed due to issues with increased noise. Similarly, Huelat connected with a company that produces a silver additive for paint, which stops bacterial growth. When the paint was tested on the hospital ceiling, however, it interfered with radio signals from transmitters used to monitor patients.

In selecting antimicrobial agents, which are being explored for cable shields, chair backs and armpads, and other items, Huelat says that the team looked for compounds that have been proven elsewhere. In their study of these materials, they are also balancing long-term exposure to hospital workers of these antimicrobial agents versus the exposure workers currently have to caustic cleaning agents.

To address the need to rapidly expand the capacity in a crisis, Huelat increased the size of the patient rooms by 15 to 20 percent over the traditional design so that a single-patient room can quickly accommodate up to three patients. For a major influx of patients, the rooms are designed with breakaway doors, so that each room can serve five patients at a time. This creates efficiencies for the nurses and physicians while speeding the treatment of patients, who would otherwise have to wait in lobbies and hallways.

A Partnership with Herman Miller

Because of their long experience in healthcare, design team members were familiar with Herman Miller’s range of solutions—clinical and administrative—specifically designed for healthcare spaces. The need for flexibility and the similarities between the ED and the financial industry led the team to look at other Herman Miller products, as well. It was Herman Miller’s design approach that cemented the partnership, however. “The design principles that go into our facility were a good fit for Herman Miller,” Dr. Smith says. “Many were the same principles that have guided Herman Miller so successfully.” As part of the design process, Smith, Huelat, and others made a trip to Herman Miller to learn about the company’s resources. Herman Miller pledged to explore options, to try different materials, and to customize products to meet the objectives of the project.

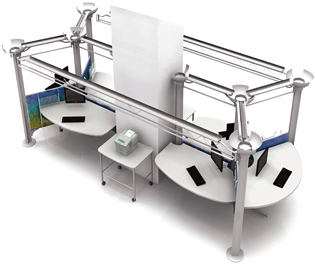

Herman Miller began by studying the work of the hospital staff members in the existing ED and asking them about how the furniture could support their work. At first, some of the members of Herman Miller’s design team were skeptical about using the company’s Resolve product, a pole-based office furniture system.

“This is the first client that said Resolve furniture could work in healthcare,” explains Jill Joseph, design team leader for Herman Miller. Joseph, who has been in healthcare design since 1984 and with Herman Miller for 10 years, wondered about putting a lighter-weight product in a high-abuse area.

But the lighter weight and ease of disassembly made the Resolve system ideal in the view of the hospital’s design team. Further, the center post, which carries the electrical and data cables, can stay in place and be used to power patient equipment in the event that the workstation is disassembled to create space for incoming patients. Huelat echoes Joseph’s comment. “Resolve wasn’t the perfect solution at the outset, but Herman Miller was willing to work with us to tailor the solution,” she says. “It was the attitude of being willing to work with us.” Herman Miller’s team customized the product by creating trusses to hang monitors above the work area to make use of vertical space, which kept the footprint smaller. Individual monitors are hung from the center poles. The design gives the staff lots of open viewing space to monitor patients. A chart shelf was developed to make it easy for physicians to pass charts through to clerks.

Franklin also notes that studies show healthcare workers will wash their hands between patients if a sink is conveniently located. In the Bridge project, sinks are placed in strategic locations, such as inside and outside of patient rooms. *7

As the design progressed, Herman Miller developed a mockup and installed it in a room adjacent to the existing ED. Herman Miller’s Workplace Metrics Research Group developed a survey for the ED staff to use to evaluate the mockup. The staff was asked to consider such things as comfort, fit (reach, height, work area), technology space, ability to focus, flexibility to support different work styles, support for communications, access to information, storage, and ease of visibility.

The survey, completed by 47 physicians and nurses, engaged the staff in the design process and resulted in several recommendations for improvements that were incorporated into the “Bridge to ER One” design. In addition, Herman Miller researchers spent time in the nurses’ station observing how the staff worked. As a result of the research and observation, Herman Miller designed what is now called the “touchdown station” rather than the traditional nurses’ station. As noted earlier, the design of these “touchdown stations” takes its cue from the trading floor.

In addition, Herman Miller advised on other aspects of the ED and designed the laboratory attached to the “Bridge to ER One” project. The separate lab was developed to isolate contamination associated with epidemics or an act of bioterrorism. Herman Miller’s Co/Struc products are used for storage in the patient rooms and a “ready reserve” room, where quantities of supplies are stored for a major influx of patients. All of those units are on wheels so they can be quickly moved into service where they are needed.

That's not going to change any time soon, Franklin says. "The devices just keep increasing. We’re in transition from paper to electronic records. We need what is going to work today and what will serve us well in the future.”

Post-Occupancy Studies

The “Bridge to ER One” opened in April of 2008. Franklin is embarking on studies of the space, particularly the contamination issues, to see if the surface treatments actually result in lower amounts of bacteria. She left some of the products untreated for side-by-side comparisons, and she is comparing the contamination levels with those in the older ED space, which is still in use. Continuing the evidence-based approach in the project, Franklin and Smith plan to publish their research for peer review.

Herman Miller is also being asked to study the performance in the Bridge space. Herman Miller’s Workplace Metrics Research Group is designing a patient satisfaction survey to see if the satisfaction levels in the new area are different than in the older ED. Herman Miller will study efficiencies and processes, such as the amount of time that it takes the clerk to move the chart from the “touchdown station” to a patient room, the time that it takes the nurse to meet with a patient, and the time that it takes to order lab work. Again, the new space will be compared to the old space. Herman Miller is partnering with RAND Corporation for these studies.

Franklin says that as the “touchdown stations” are used, the design team continues to look at ways to increase access to power and data while improving the ease of cleaning the furniture. She would also like to see product designs that further reduce crevices that can trap bacteria.

One of the stipulations for receiving federal funds for the project was that WHC share with other hospitals the knowledge gained in “Bridge to ER One” and from the ER One task forces. As a result, Franklin and Smith regularly speak at healthcare conferences and provide tours to people from hospitals that are designing new facilities.

“We are looking to be part of a paradigm shift, not just incremental advancement,” Smith says. “You need to take chances, to test things in the crucible of real experience. This is a living laboratory.”

Design Principles for ER One

KEY RECOMMENDATIONS OF PROJECT ER ONE *8

Scalability

-

Universal patient care rooms that are configurable for any purpose

-

Single patient rooms reconfigurable to accommodate up to three patients

-

Rapid conversion of non-patient care space into clinical space for 4 to 5 times scalability

-

Modular and mobile solutions rather than dedicated built-in equipment

-

Convex, multilane vehicular access

-

Emphasis on portability and modularity at every scale

-

Instant access to all data for any patient at any moment

-

Person-to-person communications net that is independent of other communications systems

Capability

-

All rooms with negative pressure capability and 100 percent non-re-circulated air

-

Every room an isolation room with separate ventilation and separate toilet facilities

-

Ability to isolate single rooms or entire zones and sectors

-

Multimode decontamination capability in every area of the facility

-

Portals for access control and threat detection

-

Universal docking capability for portable external modular treatment units

-

Robust real-time data sharing with local, state, and federal health authorities

Threat Mitigation

-

Self-decontaminating surfaces

-

Offset parking away from building footprint

-

Single-room and single-zone modular compartmentalized ventilation systems

-

100 percent air filtration

-

Assured water supply with internal purification capabilities

-

Blast protection walls and blast deflection strategies

-

Elimination or encapsulation of building materials that can shatter during an event

-

Built-in radiation protection

-

Advanced security and intrusion detection technologies

GUIDING PRINCIPLES OF DESIGN AND OPERATIONS *9

-

Scalability: The infrastructure facilitates near-immediate expansion of patients being served

-

Graceful degradation: A catastrophic collapse of systems must be avoided

-

Modularity and encapsulation: Expansion is achieved by adding new modules that have minimal dependences on other modules

-

Multiuse: Space and equipment designed for a single application are minimized

-

Doctrine of daily routine: People perform best in a stressful situation if they use tools and systems they use every day

-

Obviousness: The proper use of equipment and space is obvious to the user

-

Late binding: Decisions are made as late in the design process as possible to increase the total knowledge of the project that informs the decision

-

Self-assembly: Humans, the ultimate intelligent agent, will create solutions when given appropriate information, authority, and tools

-

“Sunshine” the data: Provide easy, obvious access to data about patients and equipment

-

Make things automatic: “Push functions” to make it easy to do the right thing

-

Shorten the feedback loops: Minimize the time that elapses between an action or decision and feedback about the results

Company Informations:

Le Office Furniture Manufacturer

www.letbackrest.com

Address: No.12, Nanhua Road, LongJiang ,Shunde,Foshan, Guangdong, China (Mainland)

Email: sale@letbackrest.com

skype: kinmai2008